Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Investigation of Emission and Performance Characteristics by using of Jojoba Oil and Tamarind with Additive in Single Cylinder C.I Engine

Authors: R. Rajadurai, M. Vivekananthan, S. Balaganesh, H. Agilan, S. Desikan

DOI Link: https://doi.org/10.22214/ijraset.2023.54591

Certificate: View Certificate

Abstract

For use as a renewable fuel in diesel engines, the current experimental study investigates the extensive potential of a unique biodiesel in the form of tamarind seed oil. Given its widespread availability at almost no cost, improved sustainability, and environmental friendliness, it is a desirable candidate for widespread use in diesel engines in a nation like India. Through the transesterification process, tamarind seed yields Tamarind Seed Methyl Ester (TSME), and Jojoba Seed Methyl Ester an effective potential fuel. Tamarind Seed Methyl Ester and Jojoba Seed Methyl Ester with diesel fuel are mixed in volumetric proportions to create different biodiesel blends like TJME 10, TJME 20, TJME 30, TJME 40 and TJME 50. Experimental evaluation and comparisons between the physio-chemical characteristics of tamarind and Jojoba seed methyl ester blends, and diesel fuel were conducted. To investigate the performance, emissions, and combustion characteristics of a diesel engine, experiments were conducted on a four-stroke, single cylinder, water cooled, direct injection diesel engine that was fueled with diesel fuel and various tamarind seed biodiesel blends, such as TJME10, TJME20, TJME30, TJME 40 and TJME 50, at a rated speed of 1500 rpm from no load to full load operating conditions. The following parameters were assessed in engine, carbon monoxide, hydrocarbons, and oxides of nitrogen, smoke opacity, heat release rate, brake thermal efficiency, and brake-specific fuel consumption. This testing phase enabled the identification of the tamarind biodiesel mix, TJME 20, whose performance is equivalent to diesel. Additionally, the findings showed that improved ignition characteristics, reduced CO and HC emissions, and a considerable reduction in smoke among the other tested fuels, emissions. However, there was a little rise in the nitrogen oxides and specific fuel consumption. The focus of this project\'s second phase was on how the characteristics of diesel engines running on TJME 20 biodiesel blends were affected by various oxygenated fuel additives acting as ignition enhancers. For this investigation, oxygenated gasoline additive were taken into consideration at varying amounts (5% and 10%) on a volume basis. Due to their greater stability, low viscosity, faster ignition rate, and rich inherent oxygen content, they were mostly employed to improve the qualities of biodiesel to a significant level. This results in the clean burning of fuels in the combustion chamber. According to the results of the trial, TSME20 with I-Pentanol fuel additive produced better performance, combustion characteristics, and lower tailpipe emissions than the other fuels that were put to the test. Enhanced air-fuel mixing, better oxidation, a higher surface area to volume ratio that led to a higher brake thermal efficiency for the TJME20 with I-pentanol blend at 36.25% was 1.9% higher than the TJME20 at peak load condition, as well as significant decreases in carbon monoxide, hydrocarbon, and smoke emissions are just a few of the benefits that the immersed I-Pentanol in the tamarind seed oil blends exhibit. According to the experimental findings, tamarind and jojoba seed biodiesel has the potential to be a significant source of alternative fuel due to its improved combustion and higher heat release rates, as well as a significant improvement in brake thermal efficiency and a significant decrease in harmful pollutants like carbon monoxide, hydrocarbons, and smoke. In addition to lowering pollutants, it will also help distributed power generation in areas where such seeds are widely produced. Last but not least, tamarind seed biodiesel is a feasible and potentially useful alternative fuel for partially or entirely replacing diesel in diesel engines in the interest of energy sustainability and the environment.

Introduction

I. INTRODUCTION

The fast depletion of crude oil resources, worldwide environmental pollution concerns, and rising fuel prices have necessitated a growing emphasis on biodiesel as an appealing renewable fuel for diesel engines. It has various advantages. like as being naturally renewable, environmentally beneficial, readily available, and economically competitive in emerging nations like as India.

Over the last few years, researchers have examined the various feedstock of biodiesel derived from Jatropha curcas, Corn seed oil, Karanja, Pungamia pinnata, Mahua seed oil, Sunflower, Soya bean, and others, and conducted extensive studies on their effect on diesel engine performance parameters. In the following domains, an extensive literature study was done as the primary phase of research activity.

Review of biodiesel as an alternate fuel for diesel engine

- Various oxygenated fuel additives

- Various nano additives as fuel catalysts

- Exhaust gas recirculation (EGR)

Shameer and Ramesh (2017) investigated the effects of a green substance on the diesel engine's performance and came to the conclusion that up to 20% biodiesel blends exhibited similar brake thermal efficiency (BTE), brake specific fuel consumption (BSFC), and tailpipe emissions with higher NOx penalties when compared to base fuel. [1]

The fixed bed fire-tube heating pyrolysis of tamarind seed oil was discussed by Kader et al. (2013), who suggested that it was a promising choice for producing bio oils from tamarind seed. This system primarily consists of a liquid condenser, collector, and fixed type fire-tube heating reactor. The pyrolyzed processed tamarind seed was in particle form. [2]

In a ground-breaking study on the manufacture of biodiesel from lemon fruit rinds, Ashok et al. (2017) also looked at the efficiency, combustion, and emissions characteristics of diesel engines. They came to the conclusion that because lemon peel biodiesel has a lower density and a lower boiling point than other biodiesel, it performs better and emits less emissions when blended.[3]

Shorea robusta methyl ester was reported to be used by Pali and Kumar (2016) as a sustainable energy source for compression ignition engines. They thoroughly looked at the characteristics of diesel engines, including heat release rate, in-cylinder pressure, thermal efficiency of the brakes, specific fuel consumption, emissions of carbon monoxide, hydrocarbons, nitrogen oxides, and smoke. They came to the conclusion that the combustion analysis revealed a decreasing ignition delay and an increasing trend in the rate of heat release. They also suggested using biodiesel as a practical fuel for compression ignition engines.[4]

In their study on the effects of alkaline catalysed transesterified soybean oil, Qi et al. (2010) found that blends of transesterified soybean oil had worse brake thermal efficiency than diesel under all load circumstances. It is mostly owing to soybean oil's higher viscosity and lower energy content. It has been observed that the soybean biodiesel blends' high surplus oxygen concentration promotes improved combustion and increased NOX emissions.[5]

According to Das et al.'s (2017) analysis of castor oil as biodiesel, biodiesel blends outperformed diesel fuel in terms of considerable reductions in hydrocarbon, carbon monoxide, and particle emissions under maximum load conditions. The scientists also noted that lower biodiesel mixes result in higher thermal efficiency and reduced fuel use for the brakes.[6]

In their experimental study, Agarwal et al. (2008) found that treating crude vegetable oil with pyrolysis resulted in the highest yield production of biodiesel with the lowest viscosity. They advised that pyrolysis be used more often. an ideal strategy for maximising yields of various biodiesel feedstock.[7]

The physio-chemical characteristics of vegetable oils, such as their viscosity, density, calorific value, flash point, fire point, and cetane number, were examined by Ferulla et al. in 2010. Vegetable oils' viscosity can be efficiently lowered using process of transesterification. They claimed that the transesterification process, which produced increased viscosity, separated glycerol from the vegetable oil. The creation of liquid droplets, vapour, atomization, and air-fuel mixtures, as well as the performance characteristics and exhaust emissions of diesel engines, are all significantly influenced by the viscosity of the fuel.[8]

Samuel et al. (2016) investigated rubber seed oil's accessibility and suitability for use in compression ignition engines. In Sub-Saharan nations, there is a significant increase in interest in the bulk production of rubber seed oil, which is produced at a rate of 17,947.339 tonnes annually and equals 16,691.025 tonnes of biodiesel for sustainable development.[9]

The availability and suitability of rubber seed oil in compression ignition engines were investigated by Samuel et al. in 2016. In order to replace some of the diesel fuel in compression ignition (CI) engines and promote sustainable development, the Sub-Saharan nations produce a large amount of rubber seed oil, 17,947.339 tonnes annually, which is equivalent to 16,691.025 tonnes of biodiesel.[10]

Dennis et al. (2010) conducted research on bio diesel and discovered that it is the best substitute for diesel fuel due to its technical acceptability and accessibility. Numerous experts reported commendable experimental work about the extraction of bio diesel from various by-products of the green plants. When compared to non-renewable fuel, biodiesel has more cetane value, less sulphur, inherent oxygen availability, and improved lubricating ability, all of which contribute to better combustion.[11]

According to experiments done by Gautam et al. (2013) using blends of methyl and ethyl esters with jatropha, at a maximum condition of load, brake thermal efficiency was improved by 11% for a 20% blend of jatropha methyl ester and marginally for a jatropha ethyl ester when compared to diesel fuel operation.[12]

Mishra et al. (2012) showed that a biodiesel blend of 10% concentration results in considerable emission reductions of 12% carbon monoxide and 25% oxides of nitrogen. They employed calophyllum vegetable oil blends with diesel at various percentages. However, there was a little decrease in brake thermal efficiency under all diesel engine running situations.[13]

In their 2016 study, Santhosh and Padmanaban explored the use of cotton seed oil as a biodiesel in diesel engines. They found that the cotton seed methyl ester blends had a shorter ignition delay period than diesel and that the amount of carbon monoxide and hydrocarbon emissions was reduced at lower cotton seed methyl ester concentrations in the diesel fuel.[14]

According to Kamal et al.'s (2014) analysis of a diesel engine running on a diesel/biodiesel blend made from used cooking oil, injection retardation of 50 degrees crank angle greatly reduces hazardous exhaust emissions such carbon monoxide, carbon dioxide, hydrocarbons, and smoke.[15]

In order to minimise viscosity, Hazar and Aydin (2010) warmed the raw rapeseed oil. This technique led to a significant decrease in CO and HC emissions with just a little decline in performance indicators. The increased NOx emissions from biodiesel are one of the main obstacles preventing its widespread use in diesel engines.[16]

Ayetor et al. (2017) carried out experiments using a variety of biofuels, including palm kernel oil, coconut biodiesel, and jatropha biodiesel, at varied injection pressures and timings. According to the findings, the most important factor influencing exhaust emissions and engine performance is injection time.[17]

The effects of biodiesel and its mixes on the efficiency and emissions of CI engines were examined by Rao et al. (2017). They came to the conclusion that biodiesel may offer diesel-like performance and emission characteristics. According to the test results, there was a little increase in nitrogen oxides when advanced biodiesel fuel injection was used instead of diesel fuel.[18]

The use of pine oil as a viable alternative fuel for diesel in diesel engine applications was reported by Tamilselvan and Nalluswamy (2015). The experimental results showed lower emissions of carbon monoxide and hydrocarbons and higher emissions of carbon dioxide and oxides of nitrogen when compared to diesel fuel when operating at full load.[19]

Using waste plastic oil and its mixes as fuel, Kumar et al. (2016) tested a direct injection, water-cooled diesel engine. When compared to the tested fuels when analysed with diesel at all load operations of the diesel engine, they discovered that the 10% waste plastic oil biodiesel mix had higher perform.[20]

Although several researchers have examined a wide variety of biodiesel feedstock, tamarind seed oil as biodiesel in diesel engines has not yet been the subject of a focused investigation. Except for some modest literature on the availability of tamarind fruit and its general applicability in numerous sectors, there is actually no technical literature on the performance, combustion, and emission characteristics powered by tamarind seed oil.

Therefore, the proposed effort seeks to provide a methodical approach for using tamarind seed oil as a biofuel in CI engines for the substitution of diesel fuel to some extent. The addition of various fuel additives to tamarind seed biodiesel also takes a unique approach; this study is the first of its type to appear in the literature.

The oxygenated fuel additives diethyl ether (DEE), dimethyl carbonate (DMC), and n-amyl alcohol (NAA) are the prospective sources of alcohols that may possibly improve the spray, according to the research review. Ternary biodiesel blends made from tamarind seed methyl ester are atomized. Additionally, it is claimed by the research findings that adding nanoparticles to biodiesel improves engine performance while significantly reducing exhaust pollutants. Alumina nanoparticles (ANP) and carbon nanotubes (CNT) are two different types of nanoparticles that are used in the mix of tamarind seed methyl ester in the current work to investigate the diesel engine characteristics.

Additionally, it is evident from prior research that diesel engines may be able to operate on a variety of biodiesels with improved performance and increased NOX emissions. Therefore, it is necessary to lower the greater NOX emissions that the biodiesel-powered diesel engine produces. The current study additionally explores how the tamarind seed methyl ester biodiesel blend's performance and emissions characteristics are influenced by EGR rates of 10%, 20%, and 30% on a volume basis.

The present experimental work primarily focuses on a number of different elements, which are listed below. Using the transesterification method,

- Tamarind biodiesel production by using transesterification process.

- Determination of physical and chemical properties of tamarind seed oil and its validation with respect to base fuel.

- Evaluation of diesel engine characteristics powered with (i) diesel (ii) tamarind seed methyl ester blends and comparison between them.

- To analyze the experimental results of tested fuels and to optimize the biodiesel blend.

- To enhance the engine characteristics with the use of fuel additives to optimum blend.

II. EXPERIMENTAL SETUP

A four-stroke, one-cylinder, naturally aspirated, water-cooled, direct-injection, compression-ignition engine was used for the experimental research. The experimental test setup is depicted schematically in Fig.

In India, these diesel engines are frequently used in portable generators and irrigation systems. The Kirloskar TV1 diesel engine, which has a displacement capacity of 661 cc and a compression ratio of 17.5:1, is used for the analysis. At an estimated speed of 1500 rpm, the diesel engine produces 5.2 kW. With a typical injection pressure of 200 bar, the manufacturer's recommended injection time was 23 BTDC. Under various load conditions, the controlling mechanism was employed to regulate the diesel engine's speed. The diesel engine's yield shaft is particularly connected to a swirl current dynamometer for providing load.

It is equipped with the tools needed to measure crankangle and combustion pressure. Through the engine indicator, these indicators are connected to a computer to display a pressure-volume diagram. Additionally, there is room for the interface of load monitoring, temperature, fuel flow, and airflow. A stand-alone panel box with an air box, a fuel tank, a manometer, a fuel measuring device, transmitters for monitoring the flow of both air and fuel, a process indicator, and an engine indication is part of the setup. Rotameters are available for measuring the water flow in calorimeters and cooling water. Fig. shows the viewpoint of an exploratory experimental engine arrangement.

Table 2.1 Technical specifications of the diesel engine setup

|

Parameter |

Specification |

|

Make |

Kirloskar TV1 |

|

Description |

Single cylinder, four stroke, Compression ignition engine |

|

Type of injection |

Direct injection |

|

Type of cooling |

Water cooled |

|

Rated Power |

5.2 kW |

|

Rated Speed |

1500 rpm |

|

Bore |

87.5 mm |

|

Stroke |

110 mm |

|

Compression ratio |

17.5:1 |

III. EXPERIMENTAL TEST PROCEDURE

In the beginning, tests were run outside using diesel gasoline to get baseline data. The diesel engine was allowed to operate steadily at 1500 rpm for around 30 minutes to achieve steady state at zero load operation. Then, using an eddy current dynamometer, it was gradually loaded from zero loads to maximum load.

All biodiesel samples were tested while the necessary observations were recorded. The diesel engine used for all of these experimental experiments had a compression ratio of 17.5 and injection pressures of 200 bar and 230 bar before TDC. Initial observations included the ambient temperature and diesel engine parameters. For the smooth operation of the diesel engine, cooling water circulation was supplied for the eddy current dynamometer, engine, calorimeter, and piezo sensor.

- Maximum load (W) is evaluated from the engine specifications.

- Fuel, lubricating oil and cooling water supply are checked.

- The set up is started and run at no load for 30 minutes.

- Power supply is given to computer and AVL data acquisition system.

- Confirming the input data to diesel engine.

- Load is increased gradually on the engine.

- Time taken for 10 cc of fuel consumption and exhaust gas temperature are recorded.

- The manometer head of water column are recorded.

- Exhaust gas emissions and smoke emission are measured.

- Wait for steady state (for @ 3 minutes) log the data in the AVL data acquisition system.

- Decrease the loads gradually.

- Results and performance plots are viewed and verified.

- The above steps are repeated for all the prepared fuel samples.

IV. RESULTS AND DISCUSSION

In primary stage, the experiments were conducted on the four stroke single cylinder water cooled diesel engine at constant speed (1500 rpm) with different loads of 0%, 25%, 50%, 75% and 100% for the diesel and various blends of tamarind seed methyl ester (TSME) such as TSME10 (90% diesel and 10% tamarind seed methyl ester), TSME 20(80% diesel and 20% tamarind seed methyl ester) and TSME30 (70% diesel and 30% tamarind seed methyl ester). The effects of load on performance, combustion, and emission characteristics for diesel and diesel-tamarind seed biodiesel mixes were discussed. According to the results of the examination of TSME biodiesel blends, TSME 20 is the best blend.

When the findings were analysed using diesel fuel, greater performance characteristics were discovered. In addition, the effect of nanoparticles added to the TSME 20 was investigated to determine the impact on diesel engine characteristics. Finally, the current experimental study focuses on the utilisation of exhaust gas recirculation (EGR) rates of 10%, 20%, and 30% to TSME 20 biodiesel mix to analyse diesel engine characteristics.

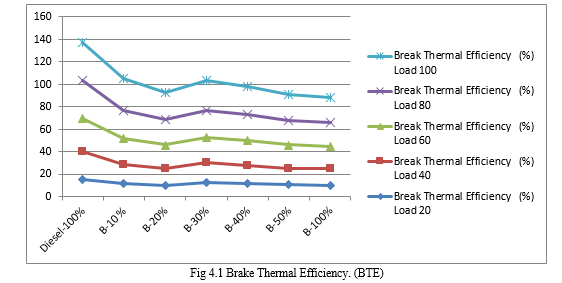

A. Brake Thermal Efficiency. (BTE)

Fig.4.1 depicts the fluctuation of brake thermal efficiency with brake mean effective pressure (BMEP) for tamarind seed methyl ester blends and diesel. It denotes the efficient conversion of chemical energy in fuel to heat energy, which is then converted to mechanical energy at the engine shaft. BTE is primarily determined by the heating value of the fuel and the amount of fuel consumed. figure that the increases in brake mean effective pressure has enhanced the BTE for all experimented fuels. It is noticed that BTE of TSME 20 blend is marginally lower than that of diesel at maximum BMEP. The slight decrease in BTE is owing to lower energy content of TSME20 blend. Furthermore, the air entrainment inside the combustion chamber could also play a significant role in total combustion phenomena. The BTE for the diesel is 34% at maximum load condition. It has been noticed that at higher concentration of biodiesel blend (TSME 30), the BTE is lower than diesel. The reduction was additionally because of lower calorific value and higher viscosity results in low vaporization and incomplete burning of TSME blends when contrasted with petroleum diesel.

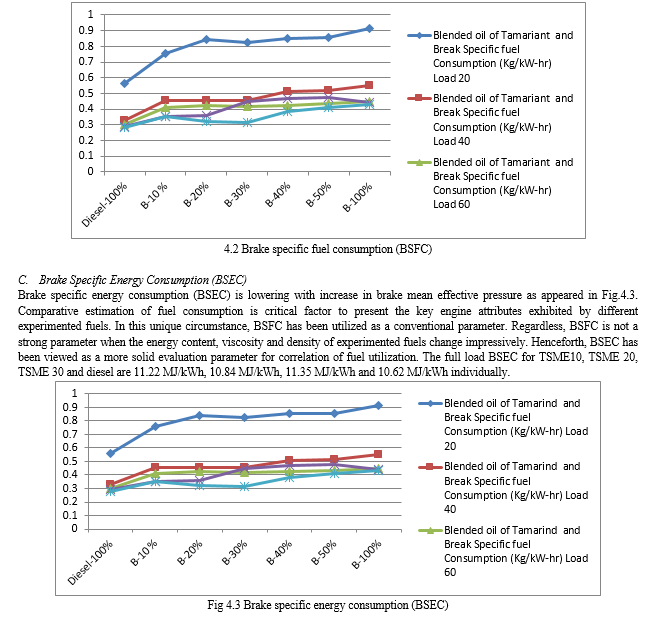

???????B. Brake Specific Fuel Consumption (BSFC)

Brake specific fuel consumption (BSFC) is reducing with increment in brake mean effective pressure as depicted in Fig.4.2. The BSFC at first declines strongly with increment in BMEP up to 50% and afterward diminishes insignificantly with advance augmentation in BMEP. It is an indication of burning effectiveness of the fuel. BSFC is lowest for the diesel among the tested fuels. For tamarind seed methyl ester blends, BSFC of TSME 20 is slightly higher than diesel. However, it is observed that the BSFC of TSME 20 blend is about 3.84% and 9.6% lower than the TSME10 and TSME 30 blends respectively at maximum brake mean effective pressure. The brake specific fuel consumption values are 0.27, 0.256 and 0.285 kg/ kWh for TSME10, TSME 20 and TSME 30 respectively, and for the diesel fuel, it is 0.245 kg/kWh at maximum BMEP. The explanation behind higher BSFC of TSME biodiesel blends are for the most part due to lesser energy content and more viscosity when contrasted with diesel fuel. Subsequently, more fuel is required for a similar power yield reported by Mishra et al. (2012).

???????

???????

Conclusion

The focus of the ongoing exploratory study is on using tamarind seed oil as an infinitely renewable substitute for diesel in compression ignition engines. investigations on a single-cylinder diesel engine operating at 23 degrees before TDC were carried out as conventional injection timing and a rated speed of 1500 rpm. The main findings of this experimental performance study were summed up as follows: 1) The novel use of Tamarind Seed Methyl Ester (TSME) offers numerous advantages, including better diesel engine characteristics, noticeably lower levels of emission, economical, highly sustainable, and eco-friendly environment 2) TSME 20 demonstrates a superior execution and closer emission to diesel than that of other blends. It is discovered that the maximum braking thermal efficiency of the TSME 20 mix is 34.14%, which is quite similar to diesel fuel. When compared to diesel, 3) The exhaust emissions of a diesel engine running on tamarind seed oil produced closer values for CO, HC, and NOX. At maximum braking mean effective pressure, the smoke opacity for the TSME20 biodiesel mix is 26.14% lower than that of diesel fuel for all of the tested fuel samples, 4) Peak cylinder pressure occurred between an 8° and 11° crank angle ATDC, with the TSME 20 blend showing the highest cylinder pressure among the four biodiesel mixes. According to the results of the experimental evaluations, the TSME 20 biodiesel blend demonstrated improved performance and better management of dangerous pollutants including HC, CO, NOX, and smoke emissions.

References

[1] Kader M.A, Islam M.R, Parveen M, Haniu H, and Takai K. “Pyrolysis decomposition of tamarind seed for alternative fuel”, Bio resource Technology, Vol. 149, 2013, pp.01–07. [2] Shameer P.M and Ramesh K. “Green technology and performance consequences of an eco-friendly substance on a 4-stroke diesel engine at standard injection timing and compression ratio”, Journal of Mechanical science and Technology, Vol. 31, No.3, 2017, pp.1497-1507. [3] Raju V.D, Kumar K.K and Kishore P.S. “Engine Performance and Emission characteristics of a Direct Injection Diesel Engine Fuelled with 1- Hexanol as a Fuel additive in Mahua Seed Oil Biodiesel Blends”, International Journal of Thermal and Environmental Engineering ,Vol.13, No. 2 , 2016, pp. 121-127. [4] Ashok B, Raj T.K, Nanthagopal K, Krishnan R and Subbarao R. “Lemon peel oil–A novel renewable alternative energy source for diesel engine”, Energy Conversion and Management, Vol.139, 2017, pp.110–121. [5] Pali H.S and Kumar N. “Combustion, performance and emissions of Shorea Robusta methyl ester blends in a diesel engine”, Bio fuels, Vol. 7, 2016, pp. 447-456. [6] Qi D.H, Chen H, Geng L.M and Bian Y.Z.H. “Experimental studies on the combustion characteristics and performance of a direct injection fuelled with biodiesel /diesel blends”, Energy Conversion and Management, Vol.51, 2010 [7] Das D, Vipul Pathak, Yadav A.S, and Rojit Upadhyaya. “Evaluation of performance, emission and combustion characteristics of diesel engine fuelled with castor biodiesel”, Bio fuels, Vol.8, 2017, pp.225-233. [8] Agarwal D, Kumar L and Agarwal A.K. “Performance evaluation of a vegetable oil fuelled compression ignition engine”, Renewable Energy, Vol.33, 2008, pp.1147-1156. [9] Ferulla F.K, Odro E.K, and Hammond D.E. “Optimization of the transesterification reaction in biodiesel production”, Fuel, Vol.89, 2010, pp. 36- 42. [10] Samuel E.O, Sunny E.I, Anselm I.I and Diakanua B.N. “Rubber seed oil: A potential renewable source of biodiesel for sustainable development in SubSaharan Africa”, Energy Conversion and Management, Vol.110, 2016, pp. 125- 134. [11] Saravanan S, Nagarajan G, Rao L.N.G and Sampath S. “Role of a biodiesel blend in sustaining the energy and environment as a CI engine fuel”, International Journal of Energy and Environment, Vol.2, 2011, pp.179-190. [12] Xue J. “Combustion characteristics, engine performances and emissions of waste edible oil biodiesel in diesel engine”, Renewable and Sustainable Energy Reviews, Vol.23, 2013, pp. 350–365. [13] Dennis Y.C.L, Xuan W and Leung M.K.H. “A review on bio diesel production using catalyzed transesterification”, Applied Energy, Vol. 87, 2010, pp.1083- 1095. [14] Gautam R, Kumar N and Sharma P. “Comparative assessment of performance, emission and combustion characteristics of blends of methyl and ethyl ester of Jatropha oil and diesel in compression ignition engine”, SAE International, 2013, 01-2664. [15] Mishra C, Kumar N, Sidharth and Chauhan B.S. “Performance and emission studies of a compression ignition engine on blends of calophyllum oil and diesel”, Biofuels, Vol. 3, 2012, pp.50-57. [16] Santhosh M and Padmanaban P. “Experimental investigation on engine performances, combustion characteristics and emission of exhaust gases of VCR engine fuelled with cotton seed oil methyl ester blended with diesel”, International Journal of Green Energy, Vol.13, No.14, 2016, pp.1534-1545. [17] Kamal M.M, Elshaib A.A and Elahwany A.A. “Performance of a diesel engine fuelled by waste cooking oil biodiesel”, Journal of Energy Institute, Vol.87, No.01, 2014, pp. 11-17. [18] Khan K, Kumar G, Sharma A.K, Kumar P.S, Mandal C and Chintala V. “Performance and emissions characteristics of a diesel engine using complementary blending of Castor and Karanja biodiesel”, Biofuels, Vol.09, 2018, pp.53-60. [19] Nwafor O.M.I. “Emission characteristics of neat rapeseed oil fuel in diesel engine”. International Journal of Ambient Energy, Vol. 22, 2001, pp.146-154. [20] Hazar H and Aydin H. “Performance and emission evaluation of a CI engine fueled with preheated raw rapeseed oil (RRO) – diesel blends”, Applied Energy, Vol.87, 2010, pp.786-790.

Copyright

Copyright © 2023 R. Rajadurai, M. Vivekananthan, S. Balaganesh, H. Agilan, S. Desikan. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET54591

Publish Date : 2023-07-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online